The Future of Industrial Mobility and Autonomy

Explore how industrial mobility advancements are transforming operations, boosting efficiency, safety, and scalability across industries.

Learn about innovative technologies, benefits, and future trends in this comprehensive guide to the future of manufacturing.

At the heart of the fourth industrial revolution (4IR), also known as Industry 4.0, smart manufacturing is transforming modern manufacturing operations. The smart manufacturing market, predicted to grow from $223.6 billion to an impressive $985.5 billion by 2032, has led to an increased prevalence of smart factories and smart warehouses alike.

Smart manufacturing integrates advanced technologies such as the Internet of Things (IoT), automation, and artificial intelligence (AI) into existing workflows, enabling organizations to optimize performance throughout the manufacturing lifecycle.

In this article, we’ll dive deeper into the digital transformation driving the evolution and prevalence of smart factories, along with the various principles and challenges impacting smart manufacturing today.

Table of Contents

Table of Contents

A smart factory is a highly intelligent and connected smart manufacturing facility that leverages the advanced technologies outlined above to optimize manufacturing processes. It enables real-time data collection and analysis for predictive maintenance, improved efficiency, and reduced downtime. Let’s take a look at some examples:

According to Forbes, 32% of current production lines are managed by both robot and cobot technology. Collaborative robots are designed to work alongside human operators in smart factories, revolutionizing traditional manufacturing processes.

However, unlike traditional industrial robots that operate away from humans in isolated environments, cobots are equipped with advanced sensors and safety features that enable them to detect and interact safely with humans. They can perform a variety of tasks including assembly, quality inspection, and packaging, enhancing productivity and reducing manual workloads.

Manufacturing accounts for 70% of the AGV market. Similar to cobots, automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) are transforming material handling and internal logistics in smart manufacturing, enhancing efficiency and productivity across the production floor.

AGVs follow fixed paths using predefined routes and magnetic strips or sensors to transport goods between locations within a facility. In contrast, AMRs use advanced navigation systems and AI to dynamically navigate and adapt to their environment, avoiding obstacles and optimizing their routes in real-time.

However, both these vehicles revolutionize the way work gets done by:

Cloud-based software offers scalable and flexible solutions for data management, analysis, and collaboration. By leveraging cloud computing, manufacturers can access software applications and store vast amounts of production data, such as equipment performance and production data, securely over the internet.

For instance, cloud-based manufacturing enterprise resource planning (ERP) software, such as SAP S/4HANA Cloud and Oracle Cloud ERP, eliminate the need for on-site infrastructure and give organizations visibility into different aspects of manufacturing, like inventory and finance. This enables organizations to access real-time monitoring of processes and control of operations from anywhere.

Around 75% of companies in advanced industries are harnessing digital twin technology. Digital twins are highly beneficial in creating virtual replicas of physical assets and processes, whether that be a factory floor layout or individual products and components.

By leveraging data from IoT devices and sensors, digital twins can provide insights into equipment health, production efficiency, and product quality. In fact, using digital twins in their facilities, manufacturers have experienced, on average, a 13% reduction in maintenance costs and a 15% increase in efficiency.

Sensors capture real-time data from equipment, machinery, and production processes. For example, sensors integrated into cobots and AMRs are continuously collecting and transmitting data to central systems, therefore enhancing safety by helping the vehicles detect nearby objects and obstacles.

At Cyngn, for instance, our AVs use Ouster's 3D lidar sensors which bring complete 360° vision to each vehicle and therefore enhance their self-driving capabilities.

Virtual reality (VR) and augmented reality (AR) technologies provide immersive and interactive experiences for workers, significantly improving training, design, and maintenance in smart factories.

Due to its growing popularity in manufacturing, the virtual reality market is set to grow from $31.4 billion to $50.42 billion by 2031.VR simulates realistic environments, enabling trainees to practice challenging tasks in a safe and controlled setting, as well as supporting virtual walkthroughs and design visualization.

On the other hand, augmented reality (AR), often in the form of smart glasses and mobile devices, overlays digital information onto the physical world. This provides real-time guidance and data visualization for tasks like assembly, maintenance, and quality control. In fact, augmented reality has been shown to increase productivity by 32% and decrease the time it takes to complete tasks by an impressive 42%.

According to IBM, 53% of manufacturers utilize big data to gain a competitive advantage. Through big data analytics, manufacturers can extract valuable insights about their operations and uncover hidden trends, patterns, and correlations to make strategic decisions.

For example, Tesla collects vast amounts of data from sensors placed on different machinery and production lines throughout their facilities. By leveraging this data, they are better able to better predict equipment failures, optimize maintenance schedules, and improve product quality.

The first level of smart factory evolution is basic data availability. At this stage, you can start collecting a wide range of information from sensors, machinery, and other connected devices. This often includes metrics like production rates, machine uptime, and energy consumption, which in later levels allow you to better understand how your operations are performing.

Level two involves harnessing advanced analytics tools and techniques to anticipate trends, identify patterns, and uncover insights from data gathered in level one. This means you can detect anomalies, such as deviations in product quality, predict equipment failures, and optimize workflows. In doing so, organizations can typically reduce downtime, increase cost savings, and boost safety.

At this level, the data is not only analyzed, but you can also analyze data in real-time to make data-driven decisions and adjust operations. This could include anything as minor as adjusting machine parameters to anything as major as adjusting entire production schedules. By using artificial intelligence and machine learning to analyze incoming data, manufacturing facilities can better respond to changing conditions.

The last and most advanced level of smart factory evolution is action-oriented data implementation, where you can use real-time analytics to not only inform decision-making but also trigger automated actions. At this stage, manufacturing systems can autonomously adjust production parameters, schedule maintenance tasks, and optimize resource allocation based on incoming data.

Let’s explore the six principles that define smart manufacturing and are essential for manufacturers to follow in order to transform their traditional industrial practices.

This first principle involves anticipating and addressing issues, such as equipment malfunctions, before they become problems. This is typically done through proactive data analysis, which involves taking preemptive measures, to optimize operations and maintain seamless production flows.

Manufacturing systems must be designed to withstand and quickly recover from disruptions, including supply chain issues, equipment failures, or other unforeseen events. By using predictive analytics and real-time monitoring to anticipate and mitigate potential threats, manufacturers can minimize downtime and maintain productivity even in the face of unexpected challenges.

Interoperability underscores the necessity for seamless communication and integration between different systems, machines, and software within the manufacturing environment. By ensuring that all components are effectively exchanging data and working together in real-time, smart factories can achieve greater flexibility, efficiency, and scalability within their ecosystems.

This fourth principle involves minimizing waste and energy consumption. This can be done through efficient resource utilization and eco-friendly practices, which may include investing in energy-efficient technologies. By doing so, organizations can achieve not only cost savings, but also long-term environmental responsibility.

Scalability emphasizes the ability of manufacturing systems to easily adapt and expand to changes in production demands without significant overhauls. Scalable systems can accommodate growth without serious disruptions or additional investments, ensuring flexibility and agility in operations.

Lastly, the security principle focuses on the importance of protecting critical assets and proprietary data from cyber threats and unauthorized access. This includes implementing robust cybersecurity measures, such as authentication protocols, encryptions, and access controls, so that smart factories can ensure the integrity and confidentiality of their sensitive information.

Transitioning from legacy processes to modern digital systems can be difficult for manufacturers. This transition can require large up front costs in new equipment, technology, and downtime due to installations and employee training.

However, investments in new technology, such as automation, can reduce labor costs associated with repetitive tasks as well as fill any workforce gaps a facility might be experiencing. For instance, at Cyngn, we offer on-demand service, no infrastructure changes, and we work with vehicles you already use, so that organizations can experience a seamless transition from legacy processes.

Cost is typically a major roadblock for organizations because initial implementation may require substantial financial investment, such as maintenance costs, upgrades, and workforce training. For many organizations, careful consideration of costs and return on investment (ROI) analysis is essential to ensure financial viability.

However, despite potential upfront costs, this technology can help reduce costs by minimizing high hidden costs related to labor, productivity, and safety. In fact, our studies have shown that it is 50% more expensive to delay your investment in automation. By adopting smart manufacturing technologies organizations can instead combat worker shortages, boost output, and reduce downtime.

According to a study conducted by Descartes, 76% of today’s supply chain operations are being impacted by labor shortages. On top of this, labor costs for manufacturers have increased 20% since 2010. Rising labor costs coupled with unfilled positions are causing manufacturers to turn to advanced solutions, like automation, to help ease the effects of changing labor demands.

With automation, for instance, companies can increase their production with fewer workers and at the same time assign their employees to more important and valuable tasks.

In fact, studies have estimated that automation can free up 30-50% of a skilled worker’s time. This not only allows workers to focus on more valuable tasks, but it also allows organizations to get more work done without incurring extra labor costs to address labor gaps.

In 2022, the manufacturing sector constituted 24.8% of all cybersecurity attacks within the industrial world. Cybersecurity threats can jeopardize data integrity, operations, and reputation.

As outlined by the secure principle, smart manufacturing technology can actually help enhance cybersecurity by implementing real-time monitoring, access controls, and proactive vulnerability management. These capabilities mitigate risks by detecting threats early and protecting sensitive data.

As explored, AMRs play a crucial role as a key smart manufacturing technology that is revolutionizing smart factory operations. As a result, many manufacturers are investing in this technology to enhance automation, connectivity, and data collection in their operations.

For instance, Cyngn's fleet of industrial AVs can be leveraged for tasks such as transporting materials between production lines or facilities, streamlining workflows, reducing labor costs, and enhancing safety.

Smart manufacturing revolutionizes traditional industrial processes by enhancing efficiency through the integration of advanced technologies like IoT, AI, and automation. The technology optimizes resource utilization, reduces downtime, and improves product quality.

The six key principles include the proactive, resilient, interoperable, sustainable, scalable, and secure principles. These principles collectively drive the adoption of advanced technologies like IoT for real-time data collection and AI in order to optimize production processes, enhance flexibility, and improve overall competitiveness in the manufacturing industry.

Smart factories leverage advanced technologies such as IoT, AI, and automation to optimize production processes and enhance efficiency. IoT sensors collect real-time data from equipment and production systems, which is then analyzed using AI algorithms to drive insights and decision-making. This data-driven approach enables predictive maintenance, proactive decision-making, and continuous improvement.

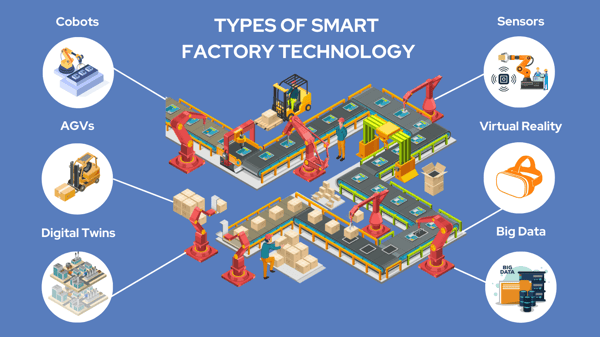

Smart factories use a variety of advanced technologies to optimize operations, including cobots, AGVs and AMRs, digital twins, and sensors. In addition, factories also leverage big data analytics for insights-driven decision-making, cloud computing for data storage, as well as augmented reality (AR) and virtual reality (VR) for training and maintenance.

Smart manufacturing refers to the integration of advanced technologies to streamline production. It encompasses the use of data-driven insights, real-time monitoring, and interconnected systems to reduce downtime and improve product quality. Smart manufacturing transforms traditional factories into agile, responsive environments that prioritize innovation, sustainability, and competitiveness.

The challenges of smart manufacturing include transitioning from legacy processes and managing the initial investment costs of implementing advanced technologies. Additionally, cybersecurity concerns, changing labor demands, and cybersecurity threats pose significant challenges in the adoption of smart manufacturing practices.

Explore how industrial mobility advancements are transforming operations, boosting efficiency, safety, and scalability across industries.

Learn how the Industrial Internet of Things (IIoT) is revolutionizing industries in 2024 by enabling real-time data analytics and enhanced...

Learn how IIoT revolutionizes operations, enhances efficiency, and drives innovation in the industrial landscape.