The Rise of Autonomous Mining Trucks and Robots

Discover how these cutting-edge technologies are reshaping traditional mining practices, improving efficiency, safety, and environmental...

Discover the latest advancements, benefits, and real-world examples of teleoperations in this comprehensive guide.

In 2022, the teleoperation market was valued at $403.2 million and is expected to grow to more than $4,367 million by 2033. Teleoperation is a growing trend that allows remote control driving and the manipulation of machines from a distance. From autonomous vehicles navigating concrete warehouse floors carrying pallets of wood to extracting diamonds in the depths of mining sites, teleoperation provides a seamless bridge between human expertise and robotic precision.

As the demand for innovative solutions to improve safety and address labor challenges grows, teleoperation stands out as a key driver in the evolution of autonomous and remotely operated systems. In this article, we’ll uncover everything you need to know about teleoperations, including how it works, its applications, and numerous benefits.

Table of Contents

Table of Contents

Imagine sitting in a comfortable room in front of a large monitor, steering wheel in hand as you’re remotely-controlling robots transporting goods that are states — or countries — away. Teleoperation is just that. Teleoperated systems transmit real-time data, enabling the operator to receive feedback and make precise adjustments as needed. This makes it ideal for human operators to drive vehicles in hazardous or inaccessible areas without being physically present.

Applications of Remotely Operated Vehicles (ROVs) span various industries, such as at mining sites where it is often dangerous for humans to enter due to harmful chemical exposure and dangerous temperatures. ROVs can autonomously navigate sites, collecting materials and vital site data. Their primary advantage lies in their ability to access areas that are challenging or dangerous for humans to enter.

Highly-automated driving uses advanced sensors, artificial intelligence, and machine learning algorithms to autonomously navigate on their own with little to no human oversight. In contrast, Fully autonomous vehicles, such as autonomous tuggers and forklifts, operate without any human intervention, relying entirely on advanced AI and sensor technologies to navigate.

Teleoperations encompass aspects of highly-automated driving. While these teleoperated vehicles include autonomous technology, such as virtual bumper and lane-keeping assistance, a human is still required to both operate and oversee these vehicles. In contrast, fully autonomous vehicles strive for complete self-sufficiency, navigating and making decisions independently without human input.

Supervised autonomy is a concept that encompasses teleoperation and highly-automated driving. In supervised autonomy, a vehicle or machine operates mostly autonomously but is monitored by a human operator who can intervene and take control if necessary. This safety net ensures reliability and safety and is useful in many industrial environments, such as manufacturing and construction, where vehicles can perform tasks autonomously but humans can intervene in the event of a malfunction or breakdown.

Take a manufacturing plant, for example, where an autonomous mobile robot (AMR) is delivering, say, pallets of metal to a workstation, a human worker can monitor its movement and manually reroute the vehicle if it encounters an unexpected obstacle or unusual conditions in its environment.

Sensors are an integral part of teleoperated systems, providing real-time feedback and environmental data to human operators. They include cameras and Lidar for on-vehicle navigation, to specialized sensors like sensor-enabled gloves operators wear for precise manipulation. These technologies enable operators to perceive the robot's surroundings, monitor its orientation, and assess environmental conditions remotely.

Low latency communication is essential for effective teleoperation, ensuring that commands from the human operator are transmitted to the robot almost instantaneously. This minimizes delay between the input and response, leading to greater precision. Technologies such as the Internet of Things (IoT) and wifi/4g and 5g cellular networks are often used to achieve the necessary speed and reliability. Solving the latency piece is often the most difficult technology to crack for emerging teleoperations companies — and when they do, these compression algorithms end up being the most valuable piece of their technology stack.

Control interfaces are the tools that operators use to interact with and control teleoperated machines, which can range from simple Playstation joysticks and touchscreens, to more advanced setups like virtual reality systems. These interfaces provide real-time visual, auditory, and tactile feedback, allowing operators to make precise movements and decisions. Effective human-machine interfaces are crucial for accurate control and operation of teleoperated robots and vehicles, particularly in complex tasks.

Direct command interfaces are more suitable for simple, direct tasks compared to control interfaces, as they allow operators to directly control specific actions of teleoperated robots or vehicles. Examples include steering wheels, keyboards, touchscreens panels, and specialized control consoles. By translating operator commands, such as turning the vehicle or changing lanes, into immediate actions, they provide real-time responsiveness and accuracy. This is particularly beneficial for tasks that require high levels of precision and quick decision-making, such as remote material handling and assembly.

As previously explored, teleoperation plays a pivotal role in the development and deployment of driverless vehicles, allowing remote monitoring and control when autonomous systems encounter complex situations or unforeseen obstacles. For instance, Nuro, a company that specializes in autonomous delivery vehicles, has their vehicles deliver groceries, meals, and packages to customers without a driver. However, in the event the vehicles encounter a complex route or obstacle in the road, a human can quickly intervene and remotely navigate them out of an unforeseen circumstance.

Teleoperation facilitates hazardous inspections by allowing operators to remotely control operated vehicles (ROVs) equipped with telemanipulators in dangerous or inaccessible environments. These systems enable operators to remotely navigate and manipulate tools in dangerous environments such as mining, as well as inspecting pipelines or underwater oil rigs.

A study conducted in Canada found that mining is the second most dangerous industry in the country, resulting in 47 fatalities per 100,000 miners per year. However, automation at mining sites can cut down the need for on-site workers by more than 50%, offering a significant reduction in exposure to dangerous inspections.

Teleoperated automated guided vehicles (AGVs) and automated mobile robots (AMRs) streamline internal transportation within industrial facilities like warehouses and factories. This contributes to enhanced logistics operations and overall productivity in industrial settings, such as in third-party logistics (3PLs), warehousing, and distribution centers.

Teleoperated robots, such as autonomous mobile robots, enhance the functionality of warehouse robots. Unlike internal transportation robots, which solely focus on the movement of goods, warehouse robots can handle additional tasks, including managing inventory and picking, packing, or sorting orders.

Operators can remotely monitor and adjust operations to optimize workflow efficiency and ensure accurate inventory management. By integrating robot teleoperation, warehouses optimize logistics processes, reduce labor costs, and enhance overall operational efficiency in dynamic and busy environments.

Telepresence robots enable remote presence and interaction for individuals in various settings, such as healthcare, education, and business. These robots use avatar-mediated interaction to provide real-time communication and mobility for users, allowing them to attend meetings, visit remote locations, or engage in social interactions without physically being present. For example, a cafe in Tokyo, Japan is run entirely by telepresence robots that are remotely operated by humans with medical conditions that severely restrict their movements. As a result, this technology not only bridges geographical distances and enhances collaboration, but also provides greater accessibility across different sectors.

Teleoperation is also integral to drone operations, enabling remote control and precise maneuvering of drones for various tasks like gathering aerial data, conducting inspections, and performing missions across industries like warehouses, agriculture, and construction.

More than 7,000 forklift-related accidents happen each year. In addition, each accident comes with additional safety inspections and worker compensation claims which cost an average of $42,000 per accident. However, with teleoperations, that same forklift can be operated remotely to eliminate the chance of worker injury.

Through remote control driving, operators can reduce the chances of accidents and injuries as well as enhance emergency response times in the event that an accident occurs. Teleoperations additionally reduces direct exposure to dangerous conditions, such as radiation, toxins, and other physical hazards.

By overseeing multiple sites at a time, remote operation reduces the need for on-site personnel, and with that, comes cost savings such as reduced travel expenses, lower accommodation costs, and minimized downtime due to more efficient resource allocation. In addition to worker costs themselves, over $250 billion are spent on workplace injuries each year. Remote operation not only reduces the costs of injury, but also enables predictive analytics and remote diagnostics that can prevent potential accidents or downtime that additionally contribute to these high costs.

In addition to remotely controlling vehicles, Teleoperations systems can monitor drivers and provide feedback that enhances operational reliability by reducing the reliance on human factors and minimizing human error in critical tasks. For instance, in manufacturing alone, 70% of errors are human-related. However, remote monitoring and control systems can operate continuously, providing round-the-clock oversight without fatigue or human limitations. This reliability ensures consistent performance, reduces the likelihood of system failures, and enables rapid response to issues.

According to Descartes, 76% of today’s supply chain operations are being impacted by labor shortages. In manufacturing alone, 2.1 million jobs could go unfilled by 2030. By enabling remote control of tasks that would typically require on-site personnel, teleoperation helps address these labor challenges. By setting up teleoperated sites in different states or even countries, organizations can access a diverse range of talent while reducing labor costs. Additionally, teleoperations enable the automation of routine tasks, freeing up skilled workers while also filling labor gaps.

AI and machine learning significantly enhance teleoperations by enabling more intelligent and adaptive autonomous technology. These advancements allow teleoperated systems to learn from data, improve decision-making, and perform complex tasks with greater accuracy, efficiency, and responsiveness, ultimately augmenting the capabilities and effectiveness of teleoperation in various applications. For instance, AI is helping to better analyze teleoperated robots' surroundings and performance insights to help enable operators to make better decisions.

Microtransit refers to flexible, on-demand transportation services that operate within small geographic areas. Teleoperation plays a crucial role in microtransit by enabling remote control and supervision of autonomous vehicles, leading to greater responsiveness in emergency situations. In addition, teleoperators can also adjust routes in real-time based on traffic conditions and other factors, leading toward greater efficiency.

Platform agnosticism is emerging as a key trend in the future of teleoperated robotics, allowing operators to use diverse hardware and software systems interchangeably. This flexibility allows for the integration of various components into a cohesive, integrated robotic system, enhancing interoperability and scalability. Consequently, platform-agnostic teleoperation systems can adapt to diverse applications and optimize resource allocation by supporting multiple platforms.

Remote trucking and logistics represent a transformative application of teleoperations by enabling remote driving and control of freight vehicles over long distances. For instance, Waymo, a company that produces autonomous driving technology for logistics and trucking, produces trucks with advanced sensors and teleoperated systems for remote control.

This advancement enhances efficiency and safety by reducing driver fatigue, addresses labor shortages, and optimizes route planning. With teleoperation, logistics operations become more flexible and responsive, ensuring timely delivery and improved supply chain management.

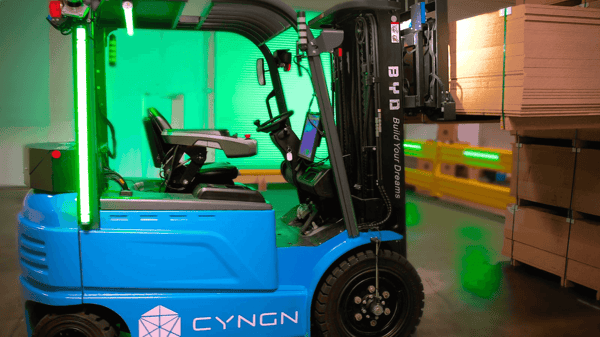

Cyngn provides advanced teleoperation solutions for remote forklift operation — at a fraction of the cost. Whether unloading trucks, conducting intricate procedures, or training new forklift drivers, our teleoperation solution enables instant connectivity to skilled professionals regardless of their location.

Our technology further eliminates the need for on-site workers, which mitigates the impacts experienced from employee churn, rising wages, and ongoing worker shortages. In addition, our platform can seamlessly aggregate all available networks, including LTE, WiFI, 5G and others, to dynamically adjust to network fluctuations in real-time to deliver the best remote operator experience.

With Cyngn’s teleoperation solutions, you can:

Frequently Asked Questions

Teledriving refers to the practice of remotely controlling vehicles or machines from a distance, often facilitated by teleoperation technologies. This concept is integral in fields like autonomous driving and robotics, where operators can intervene or guide vehicles through complex or uncertain situations.

Teleoperations offer several benefits in robotics, including enhanced safety by allowing operators to control robots from safe distances. They also improve operational reliability and efficiency through continuous monitoring and intervention capabilities, critical for maintaining system performance. These benefits collectively underscore teleoperations' pivotal role in advancing robotic capabilities and improving cost savings while addressing labor shortages.

Remotely operated robots are used in a wide range of applications where human presence is impractical or hazardous, such as hazardous inspections and internal transportation within warehouses. These robots are controlled from a distance using teleoperation technologies, enabling operators to navigate them through challenging environments and perform tasks that require precision and safety.

Teleoperations work by leveraging communication technologies with low latency, such as wifi and 4g/5g networks. Operators use various control interfaces, such as joysticks and touchscreens, to send commands to teleoperated systems. These systems utilize sensors to provide real-time feedback and environmental data, crucial for precise operation.

Driverless vehicles typically operate autonomously without remote control in normal conditions. However, teleoperation capabilities can be integrated into autonomous vehicles to allow remote human intervention when necessary, especially in complex or unpredictable situations. This hybrid approach, combining autonomous driving with remote control capabilities, enhances safety and reliability by providing human oversight when automated systems encounter challenges beyond their programmed capabilities.

Discover how these cutting-edge technologies are reshaping traditional mining practices, improving efficiency, safety, and environmental...

Discover how robots are revolutionizing the construction industry by enhancing efficiency, safety, and precision.

Playing a transformative role in modern industrial processes, factory automation empowers organizations to remain competitive and reap a wide range...