MENLO PARK, Calif., February 22, 2024 – Cyngn Inc. (the “Company” or “Cyngn”) (Nasdaq: CYN), today announced results from its customer deployment with U.S. Continental (“USC”). With a sprawling 100,000-square-foot factory, USC stands as a leading private label leather and fabric care company. USC has become the trusted partner for leading brands like Michael Kors, Birkenstock, and Monster Energy that seek top-tier commercial packaging and private label care product services. USC has enjoyed tremendous growth over the three decades it’s been in business. In that time, the company has become familiar with the hurdles intrinsic to manufacturing and distribution: supply chain disruptions, soaring labor costs, and the relentless pursuit of operational efficiency.

Download the full case study here.

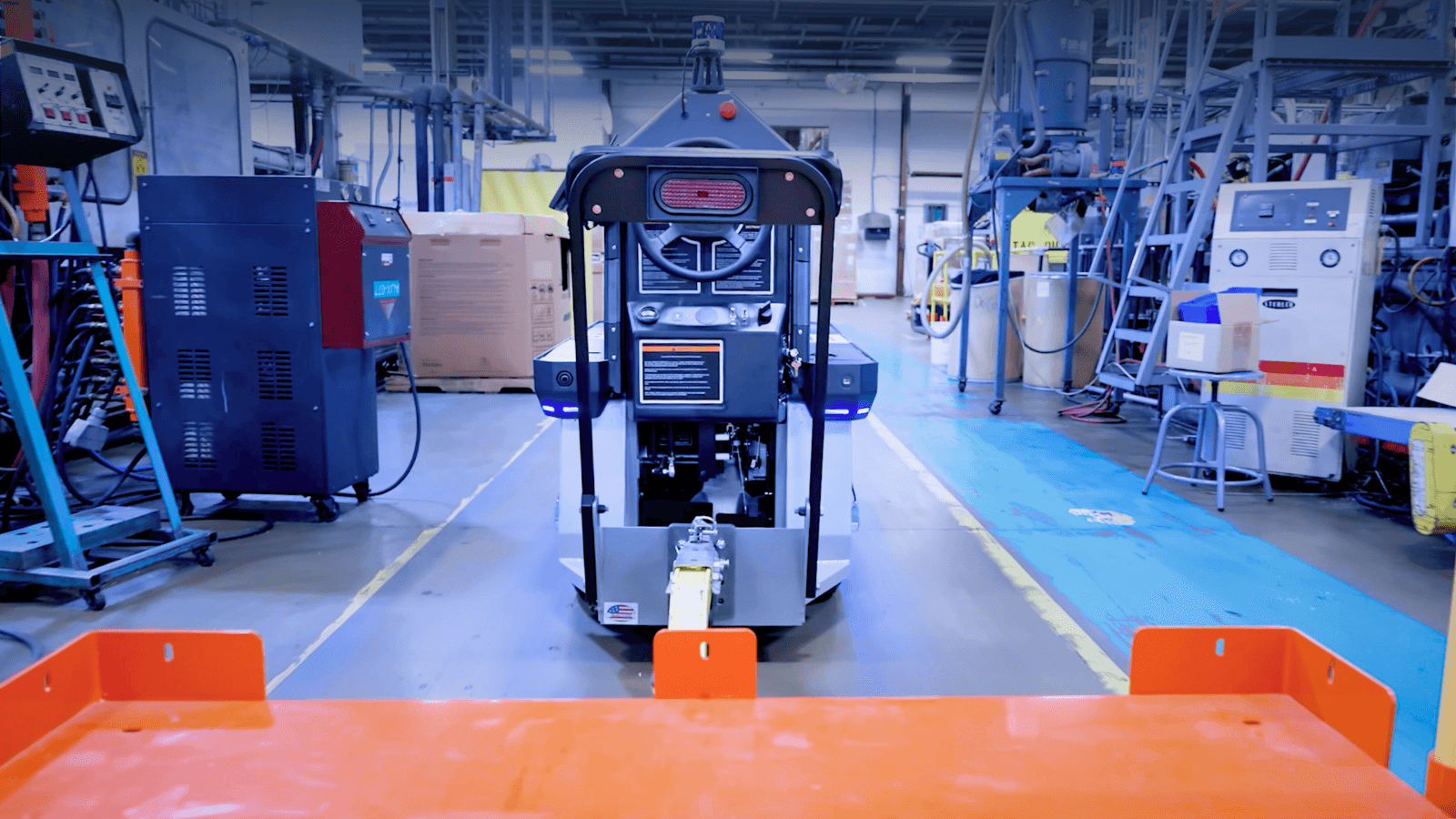

Enter Cyngn and its Enterprise Autonomy Suite (“EAS”) to offer self-driving industrial vehicles with the AI-powered DriveMod tech stack, introducing novel data and analytics about how things move at customer sites. DriveMod Stockchasers began transporting pallets around USC’s Corona, California facility in early 2023, doing supply runs between two buildings. Over several months of operation, Cyngn’s self-driving vehicles enhanced operational speed, fostered organizational precision, and delivered substantial cost savings. The DriveMod Stockchasers have produced 4x efficiency gain, and the introduction of EAS even enabled a former forklift operator’s promotion. This success led to USC recently renewing its commercial contract to extend its deployment of DriveMod Stockchasers.

Approach

Deploying DriveMod-powered vehicles at U.S. Continental, involved a simple set of steps:

- Conduct a site assessment. First, Cyngn’s customer success team worked with USC’s operations managers to obtain a thorough understanding of process flows and goals. In parallel, Cyngn’s field engineers surveyed USC’s facility to document the operational design domain (“ODD”) including the lighting, lane widths, and types of obstacles the vehicles could encounter. From this, Cyngn was able to identify transporting pallets from the inventory warehouse to the production facility as the optimal use case for the deployment.

- Build the map. In order for an AV to operate, it must know where it is within its environment. Cyngn scanned USC’s facility to create a detailed 3D representation of the physical world. DriveMod vehicles use this localization map to safely navigate within the environment with centimeter-level accuracy, which is achieved from the onboard vehicle computer and doesn’t require constant internet connection or special infrastructure installations.

- Design the application. Once the map was created, Cyngn worked with management on application design, which included the routes the vehicle would take, the stops where pallets would be loaded and unloaded onto the vehicle, how employees would interact with the vehicles, and permissible driving zones and other operating rules.

- Train key personnel. Finally, before the vehicle was let loose with full autonomous operation, Cyngn trained USC employees on safe use of the vehicle and the various interfaces available to interact with the vehicles and data dashboards. Finally, the vehicle was seamlessly integrated into daily workflows.

Curious to see our bring-up process in action? Watch it here.

While this process seems complex, it is standard operating procedure for a robotics company like Cyngn. The company recently brought up a deployment at a 1 million square foot manufacturing facility in less than 10 days.

Throughout the deployment period, the vehicle continuously collected data on vehicle usage and labor productivity in real-time. This data was used both to effectively monitor the vehicle’s performance as well as to eventually calculate cost savings.

Results

Since kicking off the deployment at USC in early 2023, the Autonomous DriveMod Stockchasers produced:

- 4x Gains in Efficiency. Previously, a substantial human effort of 200 trips per week was required to fulfill pallet delivery between the two buildings at USC. After the introduction of DriveMod Stockchasers, this workload has been seamlessly absorbed. Cyngn’s vehicles surpass traditional manual labor, as they can transport four pallets in a single trip, as opposed to one pallet at a time that was being accomplished with a forklift. This not only multiplies efficiency, but also allows for labor to be reallocated to other more valuable tasks, such as order picking and pulling.

- Reallocation of Labor. Beyond operational enhancements, the adoption of EAS and DriveMod has sparked positive developments in USC’s workforce. Opportunities for employee growth within the company have emerged, leading to promotions and role reallocations. Employees are now exposed to more digital interfaces and empowered to take on different responsibilities, contributing to a more versatile and skilled workforce. Importantly, this evolution in job roles highlights that autonomy is more about task reallocation and the creation of new opportunities than job displacement.

- Increased Organizational Precision. Teams working directly with the autonomous robots revised their workflows to better align with the vehicles’ predictable schedules. This simple change made a big difference, reducing variability, boosting overall efficiency, and making it easier to train new employees.