The shift towards autonomous vehicle technology has experienced significant growth in recent years, offering businesses across entire sectors the opportunity to streamline their operations, shore up supply and labor shortages, and transform how work gets done.

However, despite the rapid growth of the industry, there are still numerous myths and misconceptions surrounding the autonomous vehicle space. In this article, we debunk some of the most common AV myths, from the state of the industry to their potential impact on the human workforce.

Myth #1: Autonomous vehicles are still years away.

While advanced self-driving technology might still be years away on public roads, it's absolutely already here and working inside the industrial world. Compared to open road use cases, industrial applications involve more structured operations, less complex routes, lower speed requirements, predictable workflows, lower regulatory hurdles, and controlled interactions with humans.

After two decades of research, development, and beta testing, autonomous industrial vehicles have matured beyond the initial development stages. Innovators have proven the efficacy of the complex sensor technology and AI algorithms necessary for industrial automation and have begun to produce more specialized, refined vehicles. In 2021, we saw a 31% year-over-year growth in installations of industrial robots across the globe.

The industry continues to rapidly grow as organizations are forced to look for innovative ways to stay competitive and build supply chain resiliency amidst growing labor shortages and the ecommerce boom.

Myth #2: Autonomous vehicles are taking human jobs.

AVs do not take human jobs, but instead take on repetitive, mundane, and dangerous tasks. This in turn fosters a safer environment for workers and creates more satisfying work opportunities for employees who can now focus on higher value-adding jobs. This shift, therefore, helps to retain workers and allows organizations to augment their workforce to achieve greater productivity with enhanced safety.

In fact, a study at Wharton found that because robots boost efficiency and quality of work, deploying them not only increases worker retention but actually ends up generating more jobs.

Particularly, AVs help companies combat current labor shortages by improving workplaces and processes. According to a Deloitte study, by 2030, the impact of unfilled open jobs in the manufacturing industry could cost the US economy more than $1 trillion. Moreover, 50% of the 1,000 supply chain and manufacturing leaders surveyed rated hiring and employee retention as their biggest challenges.

Read more and download our industry report.

Fortunately, industrial automation provides a solution for organizations to mitigate these impacts of the labor crisis by —

- Automating dangerous, labor-intensive tasks

- Increasing operational visibility

- Improving safety and identifying hazards

- Improving efficiency

- Creating new categories of work for employees

Myth #3: Industrial automation always includes high upfront costs.

The concept of renting as opposed to purchasing vehicles is growing quickly as organizations look for new ways to cope with change — this idea is known as Robotics as a Service (RaaS). RaaS provides a new solution for businesses to tap into autonomy while avoiding the upfront investment required to shift their business.

One of the biggest advantages of the RaaS model is that by shifting from purchasing assets to renting them, costs not only become more predictable but they can also be spread out. Instead of purchasing an autonomous vehicle outright, an organization can reduce its payments by extending them out over time.

At Cyngn, our Enterprise Autonomy Suite is offered as a per vehicle monthly license. For Cyngn, the RaaS model represents the easiest way for us to put autonomous vehicle technology into a customer's hands without requiring our customers to staff up a maintenance team or hire engineers to get the most value out of such a cutting-edge investment.

Customers can kick-off an autonomous vehicle deployment for as little as $10,000.

Myth #4: You have to retire your existing fleet to invest in industrial automation.

There are millions of vehicles already out in the industrial space and many organizations don't want to discard them and purchase a whole new autonomous fleet. Fortunately, businesses can reap the benefits of industrial AVs much quicker and at a fraction of the cost by retrofitting their existing vehicles. This provides a more favorable way to harness autonomous solutions without retiring assets that have remaining lifespans.

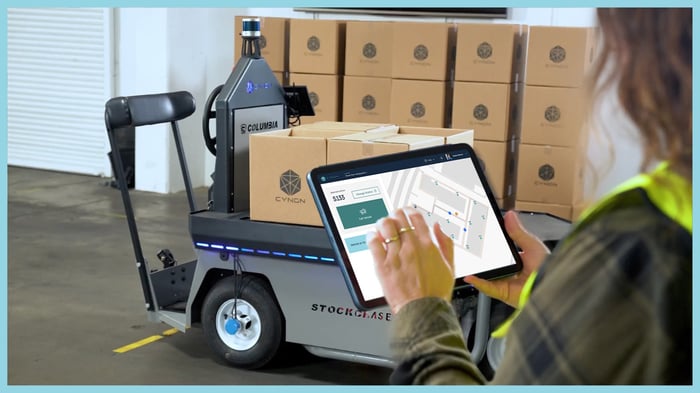

To better understand the retrofit process, consider Cyngn’s retrofit solution, DriveMod Kit, which is an all-in-one autonomy integration package. With DriveMod Kit, the entire module is installed onto a customer's existing vehicle, a calibration is run, and the autonomous vehicle is ready for autonomy in a matter of hours.

In addition to saving costs, organizations that choose to retrofit are able to do so much more quickly without having to worry about vehicle delivery times and supply chain issues.

Despite these four common myths and misconceptions, Cyngn’s AV technology allows businesses to seamlessly tap into autonomy and combat labor shortages — today.

To learn more about the ways autonomous vehicles are shaping the industries around us and check out our white paper on the topic.